No. 16011 Bridge at Lower Mills

No. 2339 This is the earliest known view of the bridge at Lower Mills. It comes from Barber, John Warner. Massachusetts Historical Collections. (Worcester, 1839).

The first real bridge across the Neponset at Lower Mills was built in 1651. Prior to that year, there was a cartway on top of the dam erected by Israel Stoughton in the 1634. The current bridge was first constructed in 1765.

The Dorchester Town Records state:

Nov. 3, 1633 … it is generally agreed that Mr. Israel Stoughton shall build a water mill, if he see cause.

Jan. 6, 1633/4 …it is ordered that Mr. Israell Stoughton shall have the privaladge of a weare at Naponset adjoyning to his mill …

Nov. 3, 1634 … it also ordered that their shall be a sufficient cartway be made to the mill at Naponset …

and from the 1859 History of the Town of Dorchester, p. 33:

The town granted leave to Mr. Israel Stoughton to build a water mill [in 1633], and in January following, the mill and a bridge over Neponset being completed …

The following is from Adams, Charles Francis. Three Episodes of Massachusetts History. (Boston, 1892). Vol. 2, 666-671.

The construction of a great coast road from Newbury, on the Merrimac, to Hingham the northern and southern limits of the Massachusetts Bay Colony was ordered by special vote of the General Court in November, 1639, two months after the Braintree church was gathered. … It followed in some degree the line of the bay shore in order to escape the difficult Blue Hill formation ; and yet it was forced to make a long detour to avoid the creeks and marshes which everywhere indent the coast, but the Neponset River was the great obstacle to be overcome and for more than twenty years that puny stream seems to have defied every colonial effort to secure a crossing which could always be depended upon. … The matter of a public-way crossing of the Neponset which could be depended on by travellers under any circumstances and at all seasons first received the attention of the General Court in 1634, the year in which Boston had ” enlargement at Mount Woolliston.” Mr. Israel Stoughton was then granted liberty to build a mill, weir and bridge at the river’s lower falls.

Five months later, at the next session of the court, an exclusive mill privilege on the Neponset was granted to Stoughton, who, on the other hand, agreed to make and keep in repair a sufficient horse-bridge over the said river,” which here was even at that time probably not one hundred feet in width : but the building of this bridge was an important event in the history of the colony, — as important as the building of the St. Louis bridge across the Missouri in the history of the nation more than two centuries later; and, indeed, the earlier effort taxed much the more severely of the two the resources of the community which attempted it. Father of a son more famous than himself, and whose name in connection with the simple but venerable hall which perpetuates his memory is a household word among the graduates of Harvard College, Israel Stoughton was a man of enterprise and substance. In the summer of 1634 he built on the Neponset the mill at which was ground the first bushel of corn ever made into meal by water-power in Massachusetts.

This prototype of all the busy waterwheels in New England stood at the foot of Milton Hill, on the Dorchester side of the stream, in the midst of a wilderness ; for it was four miles from any settlement on the north, while to the southward, Wessagusset was the nearest inhabited place. There was no road to it, and in 1634 the bridge at Stoughton’s mill was probably little more than a succession of logs thrown from rock to rock, affording passage across the tumbling stream to people on foot only. In the autumn of that year the blazed trail seems to have been converted into a bridle-path ; for the town of Dorchester then ordered a road to the mill, and voted the sum of five pounds with which to make it. This amounted to a little over one pound a mile for a road through a wilderness, and it was the scheme apparently to make a trail passable for horses, so that those having corn to be ground could get access to the mill by land as well as water. Such was the beginning of the Plymouth road through Dorchester. …

Years passed away, and the problem of crossing the Neponset was still unsolved ; yet the difficulty was one sure to force its own solution in time, for the river had to be crossed by every one journeying the length of the great coast road. Under the order of 1639 any town guilty of a default in the construction of so much of this road as lay within its limits rendered itself liable to a fine of five pounds ; and, in view of its long neglect to build a bridge, measures were taken to enforce this penalty against Dorchester. The town then petitioned the Court for a remission of the fine. This was allowed in May, 1652, but only on condition that the bridge should be constructed in pursuance of law, within three months, ” and, if not, the said fine to take place according to the court order, the making of such bridges over such river, being no more than is usual in the like case.”

Dorchester was stimulated by this pressure to action, but it seems to have been very loath to go into bridge-building ; so the town bethought itself of the clause in the exclusive grant to Israel Stoughton, in 1634, one condition of which was that the grantee should ” make and keep in repair a sufficient horse-bridge ” over the river. Israel Stoughton was then dead, but his widow owned and worked the mill ; so proceedings were begun against her. She in her turn, had recourse to the General Court, and petitioned to be discharged from her liability. After some investigation the prayer of the widow Stoughton was granted in part ; and, in view of the fact that near the mill

there was a good fording-place with a gravel bottom, she was excused from building a horse-bridge on condition that she should maintain a good foot-bridge, with a sufficient hand-rail. Satisfied with this concession, the widow seems to have adopted a policy of masterly inactivity, and the next spring the attention of the Court was called to the fact that, so far from a new foot-bridge having been built, the old bridge during the winter had been wholly ruined. Then at last, in May, 1655, the matter was taken energetically in hand. It was time. Massachusetts now numbered a population of over twenty thousand, dwelling in more than a score of towns, while Plymouth had five thousand people in five towns ; and a little river only seven miles from Boston, on the main road between the two colonies, was still unbridged, and in times of freshet must for days together have been impassable. The construction of a cart-bridge ” neere Mrs. Stough-ton’s mill was now, therefore, pronounced both a necessity and a county matter, and ordered to be undertaken at once ; a committee of six, among whom was Deacon Samuel Bass, of Braintree, was appointed, with full powers to fix the place of the structure and to contract for building it, the cost to be duly apportioned among the several towns. The committee seem to have done their work effectively, and nothing more was heard of a bridge across the Neponset. Indeed, for a whole century and a half the travel between Boston and the south shore followed the old Plymouth road across Roxbury Neck through Dorchester, and over Milton Hill by the bridge at Stoughton’s mill.

Harris, Thaddeus Mason. Chronological and Topographical Account of Dorchester. [Boston, 1804], 19.

“The bridge over this river [Neponset] uniting the town with Milton was built in the year 1651.” Note: it is unclear where Harris found this information.

The following is from

Historic American Engineering Record

Adams Street Bridge HAER NO. MA-131 HAER Mass 13-Bost, 133-

Location: Adams Street, spanning Neponset River–Boston, Suffolk County, Massachusetts

USGS Boston South Quadrangle

UTM Coordinates: 19.329400.4681700

Date of Construction 1765 (slap spans); 1847 (arches)

Engineer: Gridley Bryant (1847 arches)

Contractor: Thomas Hollis, Jr. (1847 arches)

Present Owner: City of Boston

City Hall

Boston, Massachusetts 02201

Town of Milton

525 Canton Avenue

Milton, Massachusetts 02186

Present Use: Vehicular Bridge

Significance: Adams Street Bridge has significance 1) as an example of stone-slab and stone-arch construction, once-common bridge-building technologies; 2) as the work of Gridley Bryant, a notable 19th-centuiry engineer and inventor who designed and constructed the pioneering Granite Railway; 3) as a contributing element in the Dorchester/Milton Lower Mills Industrial District (listed in the National Register of Historic Places); and 4) as a structure that recalls the important role of the granite industry in the historical development of Milton and the nearby town of Quincy.

[Note that although the document goes on to say that the bridge is scheduled for replacement, in fact the bridge was saved under and within a new bridge]

Description

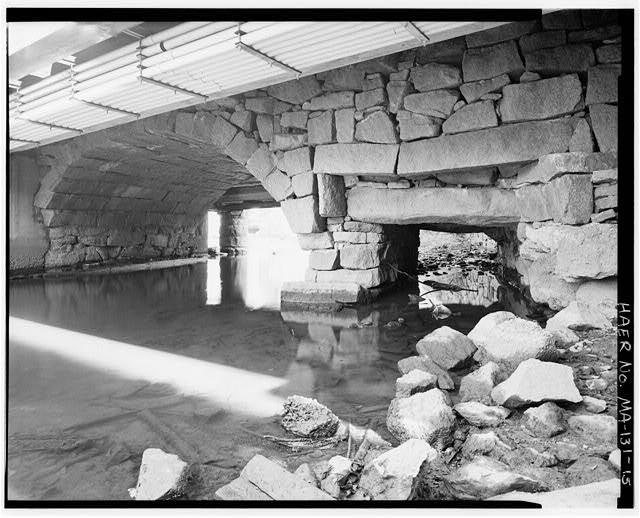

The Adams Street Bridge crosses the Neponset River between the Dorchester section of Boston on the north (Dorchester was an independent town until it was consolidated with Boston in 1870) and Milton on the south. The core of the bridge is a five-span stone structure that includes two nearly semi-circular arches about 25 feet and 30 feet in span and three stone-slab or “clapper” spans each 7 1/2 feet to 10 feet long. The arches were built in 1874, but the shorter stone-slab spans appear to be earlier and may well date from the first bridge on the site, constructed in 1765. Because the bridge has been substantially widened with concrete and steel-beam structures on both sides, the stone parts are not easily visible.

The environment of the bridge reflects the intensive industrial development of the area in the late 19th and early 20th centuries by Walter Baker & Company, a chocolate manufacturer. There is a low dam a few hundred feet upstream of the bridge and another downstream, and large multi-story brick former factory buildings are built out to the edge of the street and hug or even extend out over the banks of the Neponset River. The buildings, including a large Neo-Classical early 20th-century office building, have found new uses by a variety of commercial, residential, and light industrial tenants. The area surrounding the bridge was listed on the National Register of Historic Places in 1980 as the Dorchester-Milton Lower Mills Industrial District.

The stone portions of the bridge are constructed of roughly-shaped blocks of fine-grained gray granite, a type of stone quarried at several places in Milton and nearby Quincy, Massachusetts. Although there are remnants of sandy mortar in some joints, the stonework of both the arch and slab spans appears to have been originally laid dry, with chinking stones added to fill in the larger gaps. Beginning at the north end of the bridge, there are two stone-slab approach spans providing openings about 10 feet wide and 4 feet high; the channel for the northernmost span runs at a slight angle away from the main flow of the current. the western fascia slab for the northernmost span measures 18″ thick, 40″ wide, and 11 feet long. The next “clapper” span has a fascia slab measuring 20″ thick, 40″ wide, and 13 feet long. There is a relatively narrow course of irregular blacks above the slab stones, with an area of large-scaled quarried granite rubble above them, providing a total overburden of about 10 feet. The slabs rest on side walls or piers that are about 4 feet high and 5 feet wide; the piers have rounded noses in the upstream direction. The stonework of the piers has been mortared, and concrete has been poured around the bases as scour protection.

The two 1847 arched spans are similar to each other but vary slightly in size, with the north arch about 6 feet longer. Perhaps because of their irregularity of the stonework and the skew of the arches, the span of the north arch has been variously measured between 29 feet and 32 feet. The arches have a rise of about 12 feet. The arch rings are built of massive, square-stone voussoirs, approximately 24 feet by 24″ in section and up to about 8 feet in length; the row of stones at the apex has slipped downward 6 to 8″ in the north arch and 3 to 6″ in the south arch. The slight skew of the arches, given as 4 to 15 degrees in different sources, has been achieved by the traditional “false skew arch” technique, in which the courses of ring stones are parallel to the axis of the arch and each course is progressively offset in the direction of the skew.

The spandrels of the arches are built of large-scaled quarried granite rubble masonry. Two stones near the top of the spandrels, on the south end of the west face, are cantilevered out, possibly representing a remnant of the supports for the west sidewalk, which was built as part of the 1847 reconstruction.

The south slab span is somewhat shorter than those at the north end, about 7 1/2 feet in span, but is otherwise identical to the others. However, immediately above it is another large slab that allows the bridge to flare out toward the south abutment. the abutments consist of granite rubble masonry similar to that the arch spandrels.

Although the slab spans and the arches appear to be built of stone from the same general source, there is considerable discontinuity in other aspects. The stones in the slab spans are more irregular than the voussoirs of the arches, and their surfaces and edges appear considerably more weathered. Moreover, only the stone of arches exhibits the series of closely spaced, half-round drill marks that are associated with subsurface quarrying. With one exception (apparently a replacement), the slab stones are devoid of drillmarks; such an appearance is consistent with earlier extraction techniques, in which surface stone was split out with hammers, chisels, and wedges.

The bridge has been widened on both sides with now much-remodeled iron and steel girder-and-floorbeam structures that obscure the original stone bridge, the masonry of which is about 24 feet wide. The initial widening was undertaken on the east side in 1871 and consisted of an iron plate-girder and floorbeam superstructure carrying a plank deck and cobblestone wearing surface. The outer face of the 1871 superstructure rested on a series of seven cylindrical stone piers, which still remain. The widened portion curved northward beyond the end of the original bridge, providing a wider and somewhat re-aligned Adams Street on the Boston side, with a long, quarried granite retaining wall defining the edge of the street in relation to the river. The stone piers supporting the widened portion are about 6 feet in diameter and consist of coursed quarry-faced granite stones up to 2 high, for a total height of about 8 feet. Wide-flange cross-beams, 16″ by 12″, rest on the girders and on beams set alongside the stone bridge; some extend out over the girders to support the curving roadway. The present floor beams, concrete deck, and concrete-encasement of the girders date from a reconstruction project undertake in 1933 and 1934. One section of girder at the south end has been replaced with a concrete beam.

Two of the concrete piers that support the inner girders of the east-side widening appear to surround large granite monoliths, 32″ square. These may have been piers that supported the east-side sidewalk of the bridge as reconstructed in 1847, or they may be contemporaneous with the 1871 widening.

On the west (upstream) side the bridge as been widened about 8 feet with a large fascia I-beam carried on a concrete extension to the pier between the arches and an inner beam carried on cantilevers set into the stonework. The west-side widening was initially completed in 1900 and then rebuilt in 1926. Subsequently, one section of the fascia beam at the south end of the bridge was replaced with concrete.

The underside of the bridge accommodates a number of utilities, including an array of 32 telephone conduits along the west side and sewer and water pipes supported by added I-beams along the east side.

The various episodes of widening have given the bridge an overall width of 60 feet, including a 42 foot roadway (currently restricted on the east side by concrete barriers) and 8 foot sidewalks along both sides of the bridge. The railings, known as “Boston type,” are of welded construction and have closely-spaced 3/4″ tubular uprights between larger top and bottom pipe rails.

Because the tide in Boston Harbor typically runs a 11 feet to 13 feet, it flows back over the downstream dam, resulting in substantial changes in the water level at the bridge. As a record of the exceptionally high tide of April 1851, which was nearly 7 feet above normal, iron markers were set into the stonework on the east side; if these still exist, they have been obscured by the later widening of the bridge.

Historical Background

Although earlier there had been fords, footbridges, and a cart bridge a little downstream, the first bridge on the present site was constructed in 1765. According to an account published only a few years after the 1847 reconstruction, the original 1765 bridge was a two-span wooden structure with approach spans of stone-slab construction

The town of Milton built the southerly sluice and covered it with stone; the town of

Dorchester built the two northerly ones, and covered them with stone; the two large

ones, with the wooden bridge, were built at the joint expense of the two towns.

(History of the Town Dorchester, 1859, p. 595.)

This early account substantiates the identification of the present stone slabs as portions of the earlier bridge. Other evidence for such an interpretation includes the differing quarry marks and weathering of the stonework, the fact that the three stone-slab spans run at a level approximately 4 1/2 feet below the crown of the present arches (which is known to e on the elevation of the old bridge), and the added slab needed to bring the southwest corner of the bridge into alignment with the arches.

Adams Street was part of a major route from Boston to Dorchester, Milton, Quincy, and other South Shore communities. Laid out in the earliest years of the colony, the “Country Highway,” as it was then known, remained the sole through road in this area until 1803. In the turnpike area, Adams Street was part of both the Blue Hill Turnpike [can this be true?], organized in 1804 and running southward from a point just south of the bridge, and the Dorchester chartered in 1805 to improve the road from the bridge north to Boston.

The area that became known as Milton Lower Mills was an early trading center, since it was at the head of tidewater in the Neponset River. It also had one of the first water-powered enterprises in the vicinity, the 1633 gristmill of Israel Stoughton. Through the 18th and the early 19th centuries, Lower Mills continued to develop with new commercial and industrial enterprises, including store, warehouses, a satinet mill, and a chocolate factory.

The immediate need for rebuilding the bridge at this site was brought about by the construction of the Dorchester & Milton Branch Railroad along the south bank of the Neponset River. The existing roadway and bridge were insufficiently elevated to allow the railroad to pass below the road, but with an added 4 1/2 feet of height, the new bridge allowed the railroad to run in a tunnel (as it does today south of the bridge).

The new bridge as completed in 1847 is shown in detail on a survey prepared for the widening of Adams Street, then known as Milton Road, made by S. Dwight Eaton and on file in the records of Norfolk County. In addition to the two center arches, the three stone-slab spans are shown as they exist today. On both sides were sidewalks extending out beyond the masonry of the bridge. Judging by the remnants that remain, the sidewalks appear to have been supported by combination of cantilevered stones set into the spandrels and free-standing stone piers.

The cost of the rebuilt bridge came to about $2,700 and was shared equally between the towns of Milton and Dorchester, with Dorchester incurring a few hundred dollars in extra expenses, such as the $200 in damages paid to Walter Baker for damages to his house and store caused by raising the street level, and $242 for widening Adams Street on the Dorchester side. Dorchester also had to re-located the firehouse known as Engine House No. 1. The cost of the rebuilding, which included $100 for a temporary bridge during construction, was partly offset by $31.80 received from the sale of material from the old bridge.

The contract for the reconstruction was awarded to Thomas Hollis, Jr. (1801-1873), a prosperous local masonry contractor and supplier of stone. Hollis had inherited his granite business from his father and went on to expand it considerably, owning at least one quarry in Milton, as well as interest in various stone-cutting operations in Milton and Quincy. Hollis served as president of the Granite Railway Company from 1854 to 1864, during which time he undertook the contract for the foundation for the second Minots Ledge lighthouse east of Boston Harbor.

Although it was expensive for its day, the ridge apparently fulfilled the expectations of the local townspeople. When it was completed, the auditors of accounts for the Town of Milton made the following notation of approval:

With regard to the Bridge … the town may congratulate itself upon an acquisition

at once useful, ornamental, and permanent. (Milton Annual Report, 1848, p. 24).

The “permanent” quality of the reconstructed bridge was called into question shortly after the Civil War, when its width and alignment proved inadequate. In 1871 Adams Street was widened and re-aligned to the east so as to meet Washington Street and Dorchester Avenue, at what became known as Pierce Square. A long, curving granite retaining wall defined the new alignment of Adams Street on the Dorchester side, and the bridge was widened with the added beam structure carried on the cylindrical stone piers. The engineer for this work was Thomas W. Davis, Engineer of the city of Boston, which had annexed Dorchester only a year earlier. The bridge was enlarged on the west side in 1900, an extension that was rebuilt in 1926. The various episodes of widening reflected the increasingly urbanized and industrialized character of the area, which by that time was thoroughly dominated by the huge mills and

warehouses connected with the Walter Baker & Company chocolate manufacturing enterprise.

In 1986 the bridge was dedicated to the memory of Captain George J. Roper, a resident of Lower Mills killed in action after parachuting behind enemy lines in German during World War II.

Technological Significance

The technology embodied in the Adams Street bridge was based upon traditional stone masonry skills common in the colonies since the first years of English settlement. The use of large monoliths to bridge short spans and arches for longer spans was simply a scaling up of the techniques stonemasons used to construct building foundations and fireplaces. However, because stone bridges were more expensive than wooden spans, towns tended to reserve them for locations that were especially heavily traveled or susceptible to flood damage. Both these conditions applied to Adams Street. The road was a major highway linking Boston with the communities to the south, and the mill dam upstream of the bridge presented a hazard during high water. Today, examples of traditional stone-slab and stone-arch construction are becoming increasingly rare.

Granite was used for stone bridges in Massachusetts whenever, as in the case of the Adams Street Bridge, it was readily available. Quarrying began around 1750 in neighboring Quincy, initially working granite ledges at or near the surface. By the early 19th century, the industry was well-developed in both Quincy and Milton, with numerous quarries extracting granite that lay well below the surface. These quarries supplied most of the building stone for the numerous granite piers, warehouses, marketplaces, and public buildings that were erected in Boston in the antebellum period. Along with related stone-cutting enterprises, the granite quarries constituted a major part of the economies of Milton and Quincy throughout the 19th century.

The greatest challenge in building the Adams Street Bridge was surely the transport and the raising of the pieces of granite, some of which probably weigh in excess of 6 tons. The erection of the stone-slab spans involved simply positioning the spanning stones on top of the walls at each end. Building the arches was more complicated The usual method was to erect a wooden form, called a centering, that duplicated the shape of the desired arch; the circumference of the form was finished with planks. The cut ring stones (the largest of which in the case of the Adams Street Bridge probably weigh about 2 1/2 tons) were then lifted into position on top of the planks. After the spandrels were completed, the centering was removed.

While the large stones used in the construction of the Adams Street Bridge remain impressive, considering that they were cut with hand tools and positioned with derricks, block-and-tackle gear, and horse-power, Milton Lower Mills was surely the deal location in which to build such a structure. Since the 18th century, the necessary quarrying, stone-cutting, and masonry skills were found nearby in abundance, local contractors had wide experience with projects involving transporting and positioning huge pieces of granite, and, for the 1847 reconstruction, one of the most qualified individuals of the period was available to lay out the structure.

The designer of the arches of the Adams Street Bridge was the prominent engineer and inventor, Gridley Bryant (1789-1867). Bryant was of the generation that acquired engineering expertise through apprenticeship, self-study, and experience. He received only a common-school education in his native town of Scituate, Massachusetts, after which he was apprenticed to a “prominent builder” in Boston for several years. He eventually was place in charge of all of his employers construction projects, leaving his service around 1810 to start his own contracting business. In 1812 he worked with Harvard-educated Loammi Baldwin, Jr., on the repair and reconstruction of Bostons harbor defenses (whose father had been the engineer of the Middlesex Canal). In 1823 he was given charge of the granite work in the construction of the United States Bank in Boston, a project during which he invented what he claimed was the first practical portable derrick.

In 1825 and 1826 Bryant conceived and built the engineering work for which he is best known, the Granite Railway in Quincy. Bryant proposed the railway as a solution to the problem of moving the huge blocks of granite needed for the Bunker Hill Monument, for which he was the contractor, from the Quincy quarries to tidewater, where they were then carried to Charlestown in boats. Although it was a special-purpose system and relied on horse-power rather than locomotives, the Granite Railway is often considered a prototype for subsequent American railroads.[1] With iron-clad wooden rails laid on granite cross-ties, at a 5-foot gauge, the railway was an immediate success, and it continued in use for more than forty years after the original project was finished. In 1870 its right-of-way was incorporated into the Old Colony and Newport Railroad. In addition to the track itself, Bryant designed a series of ancillary features for the Granite Railway that became part of standard railroad engineering, including spur tracks, switches, and a turntable. Although he took out no patents, one of his innovations the 8-wheel double-truck railroad car that even today remains the industry norm, was acknowledged by the courts. Bryants prior invention provided the basis for rejecting a claim from Ross Winans that he had invented it, thereby saving millions in royalties that might have been due from the nations railroads.

Bryant served as engineer and agent for the Granite Railway Company for many years, during which time he continued to design specialized machinery and conveyances for the company, such as the wheeled vehicles used to haul the 30 foot-tall fluted Doric columns, weighing 42 tons each, used in the federal customhouse in Boston (1837). Bryant is said to have profited little from his innovations, instead supporting himself in his later years as a consulting civil engineer. At the time of the building of the Adams Street Bridge, he had an office on Court Street in Boston which he shared with his son, architect Gridley J. F. Bryant. For his services, described in the records as a survey, plan, and estimate of cost for the bridge, the two towns paid Bryant a total of $150.00. Although it may not rank among his most impressive accomplishments, the Adams Street Bridge does illustrate the bread-and-butter work of this eminent early American engineer.

BIBLIOGRAPHY

Bailey, O. H. Milton, Lower Mills, Massachusetts. Bird’s-eye view. Boston: O.H. Bailey & Co., 1890.

Boston City Directory. 1847.

Dorchester, Town of. Report of the Receipts and Expenditures of the Town of Dorchester. 1848-1849.

Dorchester Antiquarian and Historical Society. History of the Town of Dorchester, Massachusetts. Boston: Ebenezer Clapp, Jr., 1859.

Eaton, S. Dwight. “Plan for Widening Milton Road.” Manuscript, 1847, Plan Book 2, no. 160, Norfolk County Engineer’s Office, Dedham, Massachusetts.

Edwards, William C. Historic Quincy, Massachusetts. Quincy: priv. pr. 1954.

Granite Railway Company. The First Railroad in America: A History of the Origin and Development of the Granite Railroad at Quincy, Massachusetts. Boston: priv. pr., 1926.

Hamilton, Edward P. A History of Milton. Milton: Milton Historical Society, 1957.

Massachusetts Highway Department. Bridge Section. Bridge inspection files.

Milton, Town of. Annual Report of the Receipts and Expenditures of the Town of Milton. 1848

Roper, Stephen J. Massachusetts Historic Bridge Inventory. Massachusetts Highway Department, 1992.

Stott, Peter H. Inventory Form, Adams Street, Bridge, Massachusetts Historical Commission, 1987.

Stuart, Charles B. Lives and Works of Civil and Military Engineers of America. New York D. Van Nostrand, 1871.

Teele, Albert K. The History of Milton, Massachusetts, 1640 to 1887. Boston: Rockwell & Churchill, 1889.

[1] See, for example, James E. Vance, Jr., The North American Railroad: Its Origin, Evolution, and Geography (Baltimore: Johns Hopkins University Press, 1995), 18-21.